Fire Hydrant Repair and Maintenance

About Us

Precision Hydrant Services has been providing full-service fire hydrant repair and maintenance in Southwestern Ontario since 1997. We specialize hydrant installations, repairs, maintenance and inspections. All of our staff are certified, insured, and WSIB compliant, and possess Level II Water/Waste Operator’s licenses with the Ministry of Ontario.

![]()

Darryll Holland

Owner & Account Manager

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Nate Holland

Owner & Field Operator

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Save water and money by detecting leaks early.

I pulled this from Digital water solutions but should be re-written to talk about your partnership with Digital Water Solutions.

**Identify operating and transient pressure issues, reduce the risk of failure through better understanding of operational decisions, and save energy through more efficient pressure based operation.**

Hydrant Services

Protect your property and saves lives.

Our inspections meet the requirements under the Ontario Fire Code 6.6.4.

Standard

Yearly Inspection

$ 65

00

Per Hydrant*

- Flush Hydrant Lead

- Operate Branch Valve

- Pressurize Hydrant

- Painting of Hydrant

- Detailed Report

- Pull Stem

- Inspect Lower Ball Assembly

GET IN TOUCH

*Based on a 3-year contract.

Comprehensive

Yearly Inspection

$ 95

00

Per Hydrant*

- Flush Hydrant Lead

- Operate Branch Valve

- Pressurize Hydrant

- Painting of Hydrant

- Detailed Report

- Pull Stem

- Inspect Lower Ball Assembly

GET IN TOUCH

*Based on a 3-year contract.

Popular

Other Services

Fire Flow Testing

Determine your hydrants’ gallons per minute (GPM) fire flow.

Valve Turning

Prepare for emergencies by exercising watermain valves.

Painting

Prevent rust and improve your hydrants’ visibility.

Fire Hydrants are a critical investment in your property’s fire protection systems. Preventative maintenance ensures optimal operation so you can protect property and save lives.

Our flushing program reduces or eliminates discoloured water by removing high levels of chlorine.

Compliance and occupancy permit inspections ensure your hydrants are fully operational.

Products

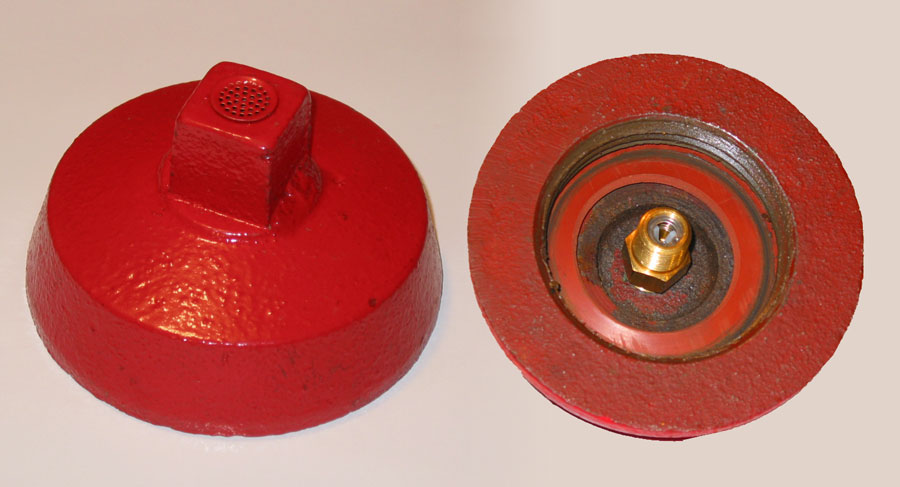

HyDrain Cap

patented

Save time and money with HyDrain, which allows operators to continue their service without waiting for hydrants to drain or needing to return to install a port cap.

Hydrant Marker

patent pending

Early detection of hydrant locations can save lives and your property. Our hydrant marker provides the highest reflective visibility on the market. With a 360° design, it can be seen by emergency responders from any direction of approach. And with year-round use, it’s the most economical marker available.

Associations & Memberships

Precision Hydrant Services is the exclusive installer of Digital Water Solutions (DWS) data loggers. DWS’s revolutionary in-hydrant data loggers provide real-time information about water main grids without interrupting service.

We are also a member of the National Fire Protection Association, which keeps us up to date on the latest industry innovations and regulatory changes.

Municipal Services

When your staffing is low and you need help completing your required annual hydrant maintenance and inspections, we’ve got you covered. Rest easy knowing that our proactive maintenance program – which also includes painting – ensures your regulatory compliance commitments are always met.

Get In Touch!

Fire Code

Fire Protection and Prevention Act, 1997

Subsection 6.6.4. Hydrants

Hydrants

6.6.4.1. Municipal and private hydrants shall be maintained in operating condition.

6.6.4.2. Hydrants shall be maintained free of snow and ice accumulations.

6.6.4.3. Hydrants shall be readily available and unobstructed for use at all times.

Subsection 6.6.5. Inspection of Hydrants

6.6.5.1. Hydrants shall be inspected annually and after each use in accordance with Articles 6.6.5.2. to 6.6.5.5.

6.6.5.2. (1) Except when in use or being inspected in accordance with Sentence (2), hydrants shall be equipped with port caps that are secured wrench-tight.

(2) The port caps shall be removed and the connections inspected for wear, rust or obstructions that in any way hamper easy removal and corrective action shall be taken as needed.

(3) If the caps are missing, the hydrant shall be examined for obstructions or accumulated refuse and flushed in accordance with Article 6.6.5.7. and the port caps shall be re-installed.

6.6.5.3. The hydrant barrel shall be inspected to ensure that no water has accumulated within the barrel when the main valve is in the closed position.

6.6.5.4. Where the hydrant barrel is found to contain water under Article 6.6.5.3., the drain valve shall be inspected for operation.

6.6.5.5. If the hydrant barrel is found to contain water because of poor drainage that is impractical to correct, approved measures shall be taken to prevent freezing during winter conditions.

Hydrant water flow

6.6.5.6. Hydrant water flow shall be inspected annually in accordance with Article 6.6.5.7.

6.6.5.7. The main valve of the hydrant shall be fully opened and the hydrant operated with one port open and the water flow checked.

6.6.5.8. A record of the hydrant operation as described in Article 6.6.5.7. shall be kept in conformance with Subsection 1.1.2.

Subsection 6.6.6. Uniform Marking of Hydrants

Hydrant marking

6.6.6.1. Hydrants shall be colour-coded in accordance with NFPA 291, “Recommended Practice for Fire Flow Testing and Marking of Hydrants”.

Links

©2021 Precision Hydrant Services